Shandong Tinwing Machinery Manufacturing Co., Ltd.

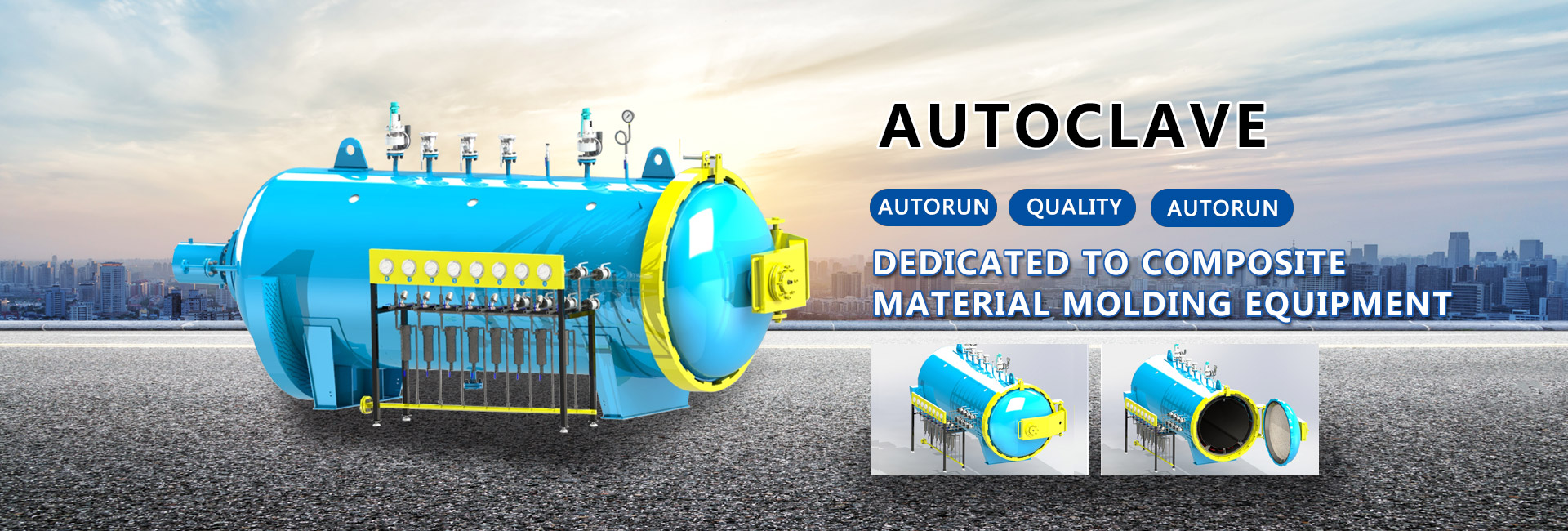

Autoclave

ClassifyAutoclave

Small composite autoclave

1、 Function of composite autoclave

The function of composite autoclave can is to use a sealed, vacuum, high temperature, and high pressure environment to heat press and solidify various composite materials, and to process them into specialized equipment. For example, metal/non-metal adhesive structural components, resin based high-strength glass fiber, carbon fiber, boron fiber, aramid fiber and other composite material products. Due to the characteristics of light weight, high strength, and long service life of carbon fiber, carbon fiber products are becoming increasingly popular, and the composite materials industry has enormous development potential. As a result, the application scope and uses of hot press cans are constantly expanding.

2、 Application Fields

Aerospace industry: aircraft wings, fuselage; Rocket shells, engine shells, aerospace structural components; Satellite celestial bodies, solar panels, etc

2. National defense and counter-terrorism: protective armor, weapons, bulletproof helmets, bulletproof vests, etc

3. Electronics industry: satellite antennas and their supporting structures, solar cell wings and shells, and other components

4. Automotive industry: locomotive body, load-bearing components, transmission shafts, engine mounts, wheel rims, etc

5 Medical fields: medical X-ray machines, CT machine frames, prosthetics, etc

6 Rail Transit: Composite high-speed trains and subway doors and windows, etc

7 Sports Industry: Composite racing components, helmets, rackets, golf clubs, jump bars, rowing boats, etc

8 Wind power generation: composite material large blades

3、 Characteristics of our composite autoclave

1. The entire process of program operation is fully controlled by PLC computer, which is easy to operate. Users only need to set the temperature, pressure, and time according to their own process, and the equipment will run automatically. Minimize manual operations as much as possible to ensure the stability and controllability of equipment operation. At the same time, it saves labor costs.

2. Users can set different process formulas for different products and save them in the system. Each time they use them, they can directly select the appropriate formula without the need for repeated settings, saving time and cost and avoiding human errors.

3. Our company selects high-quality materials and accessories to ensure that all equipment data meets the world's advanced level. During operation, the uniformity of the mold, workpiece, and air temperature inside the vacuum bag can be maintained, and the product can be accurately operated according to the set process to achieve the predetermined indicators. Ensuring product quality.

4. Our company applies progressive design concepts to greatly reduce energy consumption and improve work efficiency, which can save more than 40% energy compared to ordinary equipment and greatly reduce operating costs.

4、 Composite autoclave parameters

|

project |

data |

|

|

Effective diameter |

600-6000mm |

|

|

Effective length |

1000-30000mm |

|

|

The biggest work pressure |

0.6-5MPa |

|

|

Raise interest rates |

0.1-0.5MPa/min |

|

|

Restoration speed |

0.1-0.5MPa/min |

|

|

Pressure control accuracy |

0.001MPa |

|

|

working temperature |

100-500℃ |

|

|

heating rate (Empty load) |

0.1-3℃ |

|

|

Temperature control accuracy(display) |

±0.1-1℃ |

|

|

Uniformity of temperature field |

±2-3℃ |

|

|

Ji limited vacuum |

-0.098MPa |

|

|

Vacuum pipeline |

Customized according to customer requirements |

|

|

Heat tracing insulation |

Internal insulation, filler: aluminum silicate,100-150mm |

|

|

exhaust noise |

<75dB |

|

|

Oil tank door opening method |

Hydraulic mechanical opening, manual quick opening design (side opening), can switch the oil tank door normally when power is off |

|

|

Safe methods |

Automatic pressure interlock, manual interlock, ultra-high pressure alarm, safety valve |

|

|

control mode |

touch screen+PLCAutomatic computer |

|

|

Sealing method |

Door with silicon inflatable seal, temperature resistantfive hundred℃ |

|

|

Cooling method |

water-cooling/Liquid nitrogen cooling |

Previous:Composite autoclave

Next:Composite autoclave

Copyright ©Shandong Tinwing Machinery Manufacturing Co., Ltd.