& nbsp; & nbsp; The composite material we often refer to is a material composed of two or more materials with different properties, which are macroscopically composed of new properties through physical or chemical methods. Various materials complement each other's strengths and weaknesses in performance, creating a synergistic effect that enables composite materials to have better comprehensive performance than the original constituent materials and meet various different requirements. The matrix materials of composite materials are divided into two categories: metallic and non-metallic. Commonly used metal substrates include aluminum, magnesium, copper, titanium, and their alloys. Non metallic substrates mainly include synthetic resins, rubber, ceramics, graphite, carbon, etc. Reinforcement materials mainly include glass fiber, carbon fiber, boron fiber, aramid fiber, silicon carbide fiber, asbestos fiber, whiskers, metal wires, and hard particles.

& nbsp; & nbsp; A hot press can is a device for curing resin based composite products, which has functions such as heating, insulation, cooling, pressurization, vacuuming, detection, and automatic control. The cured products have low porosity and good quality consistency, making them suitable for curing plate and shell products.

& nbsp; & nbsp; Main technical parameters of universal hot press tank: vacuum degree: 0-0.1MPa; Positive pressure: 0-5MPa; Heating temperature: Room temperature~350 ℃

& nbsp; & nbsp; Hot press can is a commonly used equipment for curing and forming composite materials. It generates new reinforced structural materials from resin matrix and reinforcement through temperature and pressure control. It is a necessary equipment for processing and production in industries such as aerospace, automotive parts, and sports equipment.

& nbsp; & nbsp; Hot press cans can be customized according to different process requirements by setting the structure of the tank body, recording vacuum pipelines, heating power, heating rate, cooling rate, time control, etc.

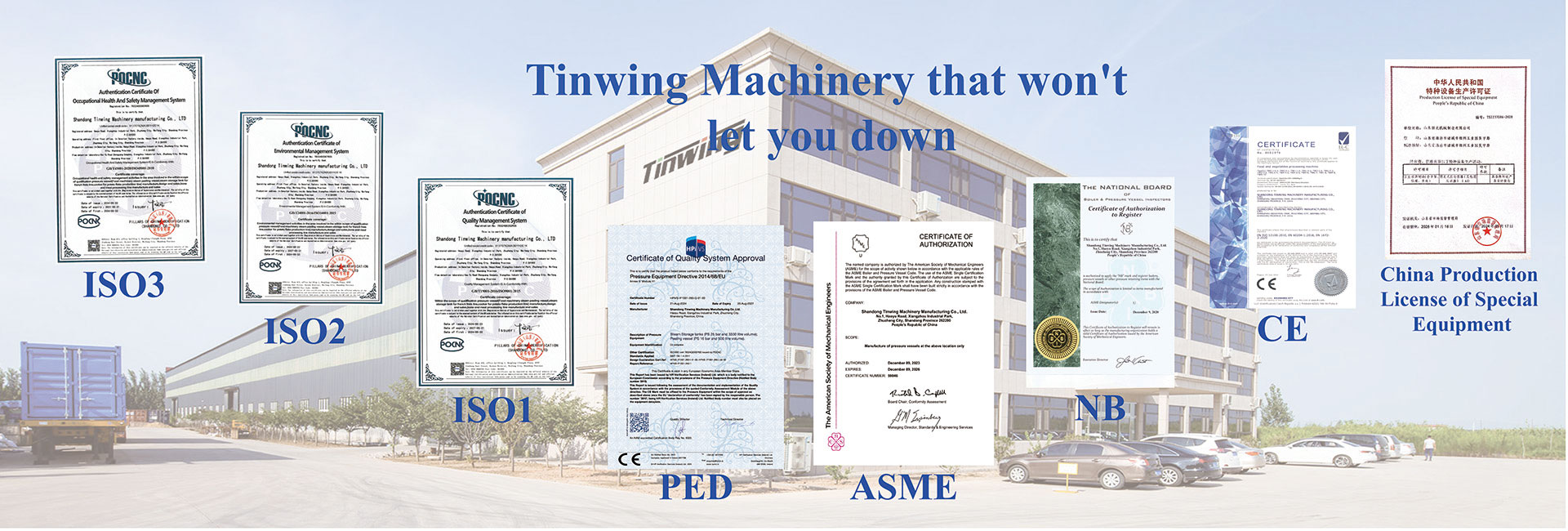

& nbsp; & nbsp; Shandong Tianyuan Hot Pot can design reasonable solutions for customers according to their requirements, and provide one-stop services such as hot pot design, manufacturing, installation, commissioning, and after-sales maintenance, until qualified products are made for customers.

Address: Xiangzhou Industrial Park, Zhucheng City

Address: Xiangzhou Industrial Park, Zhucheng City  Tel:13573651206

Tel:13573651206 Mailbox:monki@tinwingtech.com Record number:

Mailbox:monki@tinwingtech.com Record number: About us

About us Product

Product News

News Mobile station qr code

Mobile station qr code