Vacuum pressure impregnation (also known as VPI process or whole immersion process), VPI vacuum pressure impregnation equipment is an important process equipment in the production of electrical and electrical materials such as high-voltage motors, transformers, power capacitors, and paper insulated high-voltage power cables. After VPI process treatment, the insulation performance is good, the temperature rise is reduced, the work efficiency is improved, the mechanical strength is increased, the loosening phenomenon during operation is solved, insulation faults such as short circuits are prevented, the moisture-proof ability is improved, and the service life is extended.

Vacuum pressure impregnation (also known as VPI process or whole immersion process), VPI vacuum pressure impregnation equipment is an important process equipment in the production of electrical and electrical materials such as high-voltage motors, transformers, power capacitors, and paper insulated high-voltage power cables. After VPI process treatment, the insulation performance is good, the temperature rise is reduced, the work efficiency is improved, the mechanical strength is increased, the loosening phenomenon during operation is solved, insulation faults such as short circuits are prevented, the moisture-proof ability is improved, and the service life is extended.

Address: Xiangzhou Industrial Park, Zhucheng City

Address: Xiangzhou Industrial Park, Zhucheng City  Tel:13573651206

Tel:13573651206 Mailbox:monki@tinwingtech.com Record number:

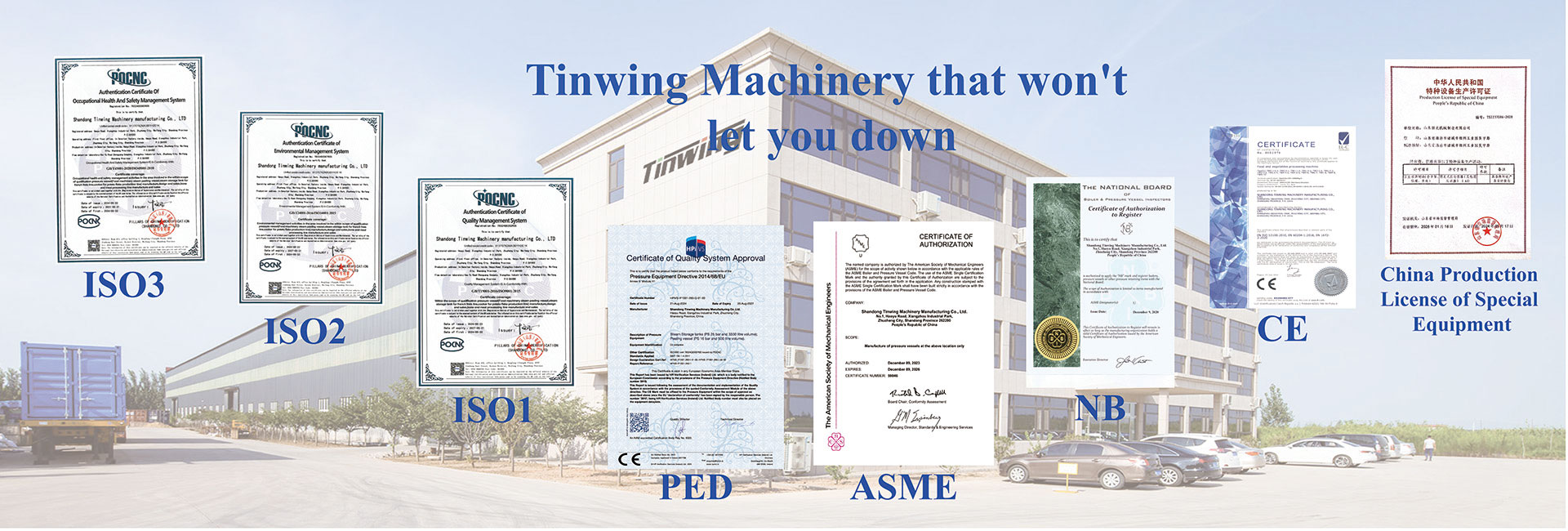

Mailbox:monki@tinwingtech.com Record number: About us

About us Product

Product News

News Mobile station qr code

Mobile station qr code